Elsewedy Steel combines industrial capacity with precision manufacturing. Our portfolio is built to international codes and supported by fully accredited testing and compliance. We deliver consistent quality, scalable volumes, and full customer confidence.

• Over 200,000 MT/year production capacity

• Certified by CARES, DCLD, ISO 9001/14001/45001

• Trusted in 30+ international markets

• Backed by Elsewedy Electric Group

• Strategically located factories in Egypt for global access

Founded in 2006, Elsewedy Steel, a subsidiary of Elsewedy Electric, is a leading manufacturer in the steel downstream and wire drawing industry. We deliver specialized, high-performance reinforcement solutions to global markets across construction, infrastructure, automotive, energy, and heavy industry.

Explore More

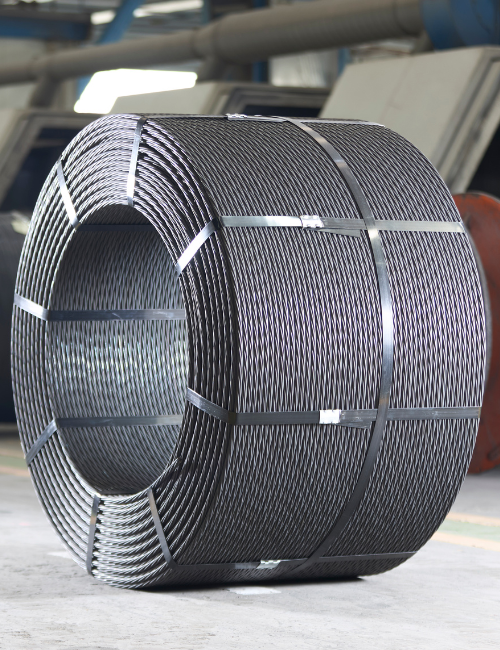

7-wire high-tensile steel strands

Designed for long-lasting structural reinforcement

Cold-drawn steel bars

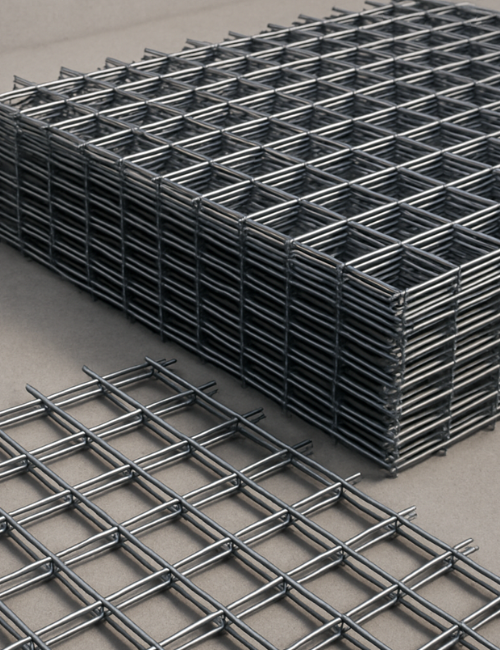

Welded Wire Mesh

Tire Bead Wire

Galvanized Steel Wire

Black Wire

Reinforcement Steel Wire

Our steel solutions are backed by international certifications, enabling seamless compliance for projects worldwide. With approvals from key institutions and a footprint across 30+ countries, Elsewedy Steel is a trusted global supplier. Our steel meets international standards and project requirements worldwide. We are certified and approved by